aluminium insect mesh

Latest articles

aluminium insect mesh

Post time: 26-04-23...

aluminium insect mesh 【aluminium insect mesh】

Read Morealuminium insect mesh

...

aluminium insect mesh 【aluminium insect mesh】

Read Morealuminium insect mesh

...

aluminium insect mesh 【aluminium insect mesh】

Read More

aluminium insect mesh

Post time: 28-04-23...

aluminium insect mesh 【aluminium insect mesh】

Read More

aluminium insect meshWe must have a certain understanding of the hexagonal net, we are swayed by the beautiful shape of the hexagonal net, not only the shape of the hexagonal net is very beautiful, in fact, the practical value of survival is very high. The introduction of the relevant information should be very clear to know the high-speed road guardrail network, hexagonal mesh of all kinds of guardrail network, the value of the high-speed road is more prominent, it is not only used in a variety of roads, in a variety of sports ball venues and landslides to take care of, but also to reach a very close utility.

...

aluminium insect mesh 【aluminium insect mesh】

Read More

aluminium insect meshSome customers do not understand the range of application of different styles of barbed rope, so there is a big difference.

...

aluminium insect mesh 【aluminium insect mesh】

Read Morealuminium insect mesh

...

aluminium insect mesh 【aluminium insect mesh】

Read More4. Substrate material: The substrate material of electrogalvanized wire also has a certain impact on its corrosion resistance. The substrate of different materials has different chemical properties and electrochemical activities, and the corrosion performance is different under different environmental conditions, and the compatibility with zinc layer will also have a certain impact on the corrosion performance.

aluminium insect mesh...

aluminium insect mesh 【aluminium insect mesh】

Read More

aluminium insect meshAfter proper heat treatment or cold drawing hardening, high carbon steel wire has high strength and hardness, high elastic limit and fatigue limit (especially notched fatigue limit), cutting function is acceptable, but welding function and cold plastic deformation ability is poor.

...

aluminium insect mesh 【aluminium insect mesh】

Read More

aluminium insect meshSolder spot, size and wire diameter of galvanized electric welding net. There are clear regulations about size and diameter of silk, as long as it meets the standard, there will not be too much difference. Galvanized welding net production is mainly welding, welding point is firm directly determine the quality of the net. Large galvanized wire purchase process need to carefully observe the solder joint, if the solder joint is too shallow, it shows that the welding is not so strong, it is easy to open welding after use.

...

aluminium insect mesh 【aluminium insect mesh】

Read More

Popular articles

- Zinc dipping time should be adjusted according to the thickness of wire diameter. The method of adjustment is to use the lead screw above the zinc pot, the length of the distance to the ceramic sinking roller. Thick wire diameter zinc dipping time should be long, fine wire diameter zinc dipping time should be short, zinc dipping length is in the range of 2~3.5m, which is also to reduce the zinc consumption of steel wire, is an aspect of maintaining the uniformity of zinc layer.

Blade thorn rope because the volume is relatively large so thorn rope factory is used to packaging treatment.

Post time: 10-11-22

Latest articles

-

Some customers are more concerned about quality problems, so for the service life is more important, barbed rope factory will generally recommend the use of high zinc barbed rope or stainless steel barbed rope.

-

Galvanized iron wire will rust, mainly and the thickness of galvanized layer and the use of the environment, galvanized iron wire is also divided into cold galvanized iron wire and hot galvanized iron wire, in general, hot galvanized iron wire galvanized layer is thicker, rust prevention time is longer, generally can be 7 or 8 years without rust. If the galvanized layer is damaged, or long-term use in a humid environment, it will accelerate the rust time of galvanized iron wire.

-

-

-

From the point of view of spray, spray blade gill net (PVC blade gill net, coated blade gill net) is also called spray blade barbed wire, spray blade barbed wire is the blade barbed wire produced in the future, to carry out anti-rust treatment. Spray surface treatment to make it has quite good anti-corrosion ability, beautiful appearance, good waterproof effect, easy construction, economic and practical outstanding characteristics. Plastic sprayed blade barbed rope is a surface treatment method of spraying plastic powder on blade barbed rope in process.

-

The galvanized requirements of the parts to be plated: the surface of the parts to be plated should be smooth, and there is no dirt that cannot be removed by pickling method. Such as paint, grease, cement, asphalt and excessive rotten harmful substances; All welds of welded components shall be sealed without air; Pipe fittings and containers must have exhaust and zinc inlet holes; The workpiece should be finished welded steel pipe without thread, if any thread should be protected.

Links

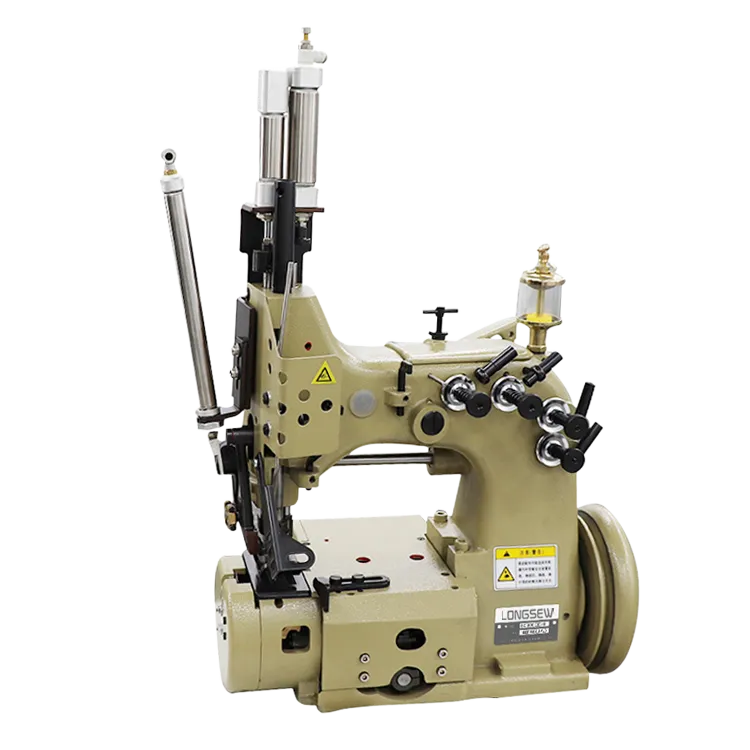

The Benefits of a Sewing Machine with Automatic Backstitch

- Additionally, overlock machines tend to have more stitch options and settings than sergers. They can create a variety of stitch widths, lengths, and styles to suit different sewing projects. Overlock machines also have differential feed mechanisms, which allow you to adjust the feed of the fabric through the machine for more precise stitching.

1. Online Retailers Websites like Amazon or specialized sewing supply stores offer a vast range of options. You can easily compare prices and read reviews from other users.